Home > Article: Depth Filtration 101

Depth Filtration 101

Simply put, depth filtration is used to remove a broad range of particles, such as dirt, grit, sand, organic solids, and rust particles. It utilizes the thickness (depth) of a cellulose-based filter media. This “depth” matrix is used to trap suspended particles, separating them from their carrying fluid. Depth filtration is most often used in polishing filtration applications including, but not limited to:

Essential oil and extract clarification

Haze removal in distilled spirits

Blood fractionation operations recovering plasma

Transformer oil filtration and water removal

Bulk chemical production

Large Volume Parenteral Solutions

Mammalian Cell removal post fermentation

Polishing filtration post fermentation centrifugation

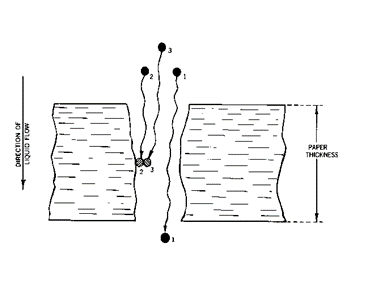

The idiosyncratic nature of depth filter media allows for fine filtrate removal with the flexibility to develop large filter cakes if needed. Depth filtration clarifies through several means of retention including sieving, interception, and absorption.

Sieving occurs when the particulate is larger than the pore spaces in the media, and therefore cannot pass through.

Due to a loss of energy interception of solids in depth media occurs. Solids must pass through a tortuous path while crossing the depth of the filter media. The loss of energy experienced traps solids within the matrix.

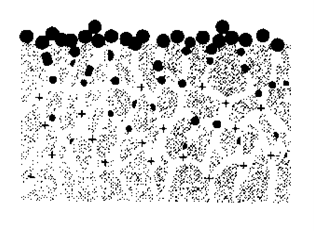

Adsorption is the adhesion of molecules to the solid structure that they are in contact with. Adsorption frequently occurs as a result of physical attraction between molecules (van der Waals force), chemical attraction at the surface/molecule interface, or more commonly in-depth media through electro-static attraction.

Our depth media is manufactured with varying amounts of wet strength resin mixed with cellulose fibres, the presence of these resins creates an inherent positive charge in our depth media filters. This positive charge (referred to as Zeta potential) generates an electro-static attraction (adsorption!) to negatively charged contaminants in the slurry stream.

Absorption characteristics within Depth Media helps to assist in the separation of water from oil-based slurries. Our depth media is manufactured from cellulose fibres which naturally absorbs water through a blotter effect. For the most efficient water removal our Aquapak which utilize a laminate and depth media combination and boasts a minimum water capture of 2.4l per square meter filter area. Applications for these include transformer oil filtration and flavour oils filtration.

A considerable advantage of Depth Media is the ability to impregnate the medium with filter aids to assist in filtration and resist blinding. Commonly Depth Media is impregnated with Diatomaceous Earth (DE), Volcanic Ash (Perlite), and Activated Carbon. The addition of filter aids offers the following additional advantages:

Advantages of DE vs. Perlite

Haze Filtration

Retention Levels

High Purity Grades

Void Volume

Advantages of Perlite vs. DE

Low Crystalline Silica Content

Wet Strength

Want to Know More?

Contact us today to find out more about depth filtration. Our team will be happy to help with any queries you may have.