PRODUCT SEARCH

Enquiries

If you have any questions about products featured on this site, or on products that you cannot find on this site, please contact us and we will be happy to assist you in any way that we can. We have a team of technical sales specialists who are waiting to hear from you!

Contact UsHome Process Solutions Contained Liquid Filtration

Contained Liquid Filtration

With dangerous or high solids process streams, standard filters can be an issue during filter change-out. Protection of the operator and the environment is paramount, and complex device handling protocols must be implemented. In a quick and extremely efficient filtration method, the FUNDASHIELD products overcome this difficulty and go further.

Fundashield combines the benefits of the Fundabac® in treating vast amounts of solids with containment for smaller batch operations, addressing the containment problem during filter element change out.

The Fundashield isolates the filter components from the environment by enclosing them in a plastic container. The whole bag is mounted inside a pressure housing for installation, but the process fluid never comes into contact with the housing. Instead, the bag is directly attached to the process piping and only the filter internals are in contact with the fluids. The operator does not come into contact with any potentially hazardous fluids when the housing is reopened for replacement of the "bag element"

The Fundashield is capable of much more than just replacing cartridge filters. The elements are back-washable and allow for cyclic operation, which greatly extends the filter's lifetime.

As a result, the filter is available in two versions:

Fundashield FC - Continuous Solids Removal

The FC variant is suitable for larger batch sizes since it allows for a cyclic slurry discharge.

In this version, the back-washed solids are flushed out of the bag through a bottom opening and can be disposed of separately. This operation extends the filter’s lifespan even further. The FC variant is suitable for larger batches sizes, allowing for a cyclic slurry discharge. An example application is a hazardous waste stream containing valuable insoluble solids (e.g. precious metals, battery chemicals – Ni, Cd, Mg) that need to be recovered. The multi-cycle approach allows for the collection of a significant number of solids for further processing and recovery.

System Configuration:

The Filter system bags are fabricated from a laminated composite film. The material in contact with the fluid is polyethene while the outer layer is a mechanically stable PA film, and because of its high tensile strength, it can withstand hundreds of cyclic operations. The filter elements within the system are made from Polypropylene and Polyethylene membrane. Because of the system's wide surface area, even very fine filtration (1um) is possible at reasonable flux rates.

Key Advantages:

Exceptional throughput

Shorter reactor downtime due to reduced cleaning requirements

Reduced heel volume and compaction of solid waste using external pressure

Fully contained and complete construction with plastics ensures safe handling and easy disposal of hazardous components (e.g. incineration)

Multi-layered plastic bag with excellent durability and long service life

The system can be manually operated or can be automated for defined process cycles

We offer fully automated bespoke systems to many of our clients to meet their unique requirements. Please contact us to discuss how we can help with your challenging application.

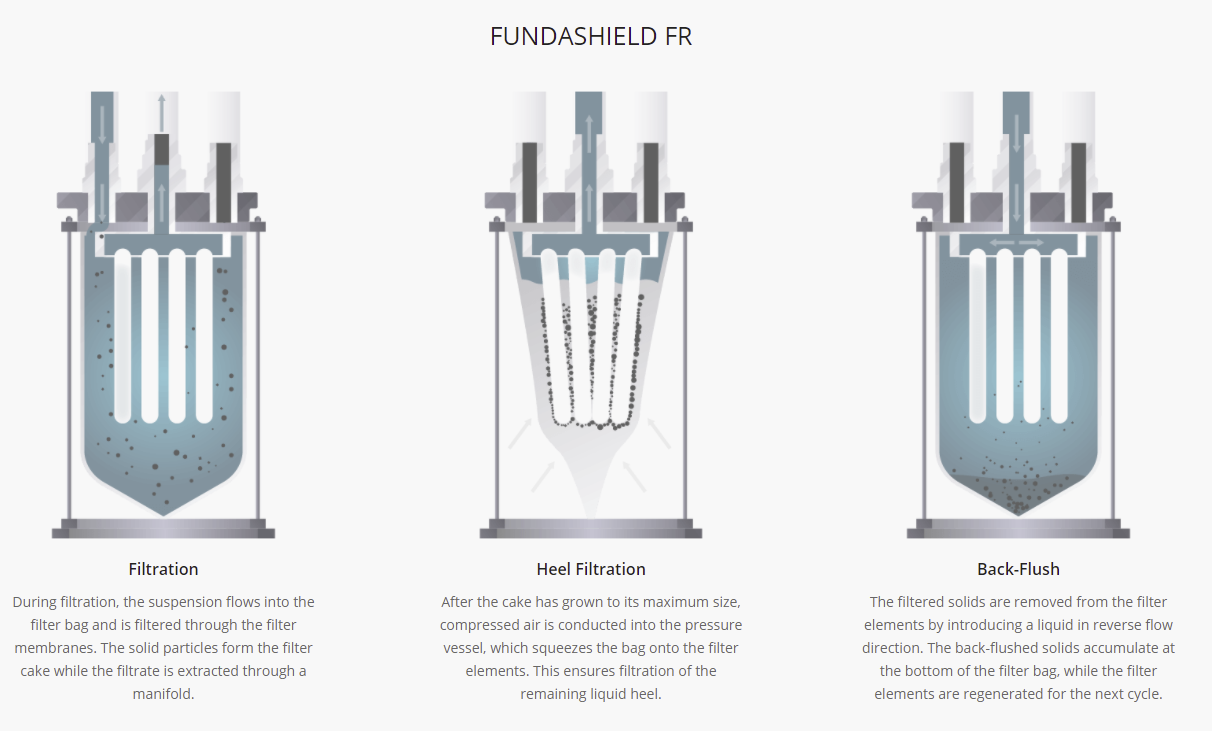

Fundashield FR - High Solids Batch

In this version, the solids within the bag accumulate in the bottom after back-washing. After a number of back-flush cycles, the bag becomes full and eventually has to be replaced. As compared to traditional cartridge filters, this makes for much greater solids loads, making it a much more cost-effective option.