PRODUCT SEARCH

Enquiries

If you have any questions about products featured on this site, or on products that you cannot find on this site, please contact us and we will be happy to assist you in any way that we can. We have a team of technical sales specialists who are waiting to hear from you!

Contact UsHome > Process Solutions > Membrane Filtration > Reverse Osmosis

Reverse Osmosis / High-Pressure Reverse Osmosis

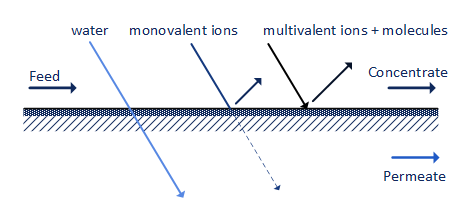

Reverse osmosis is a pressure-operated membrane process that almost entirely separates the smallest molecules, as well as polyvalent and monovalent ions from a solution. Based on a 2000 ppm NaCl solution, modern reverse osmosis membranes have retention of 99.5 - 99.8 %.

RO works analogously to NF by transport through diffusion over a dense membrane. While water can pass through the membrane, ions are almost entirely retained. The osmotic pressure of the solution, which is directly proportional to the salt concentration in the solution, determines the pressure needed to move water through the membrane.

High-Pressure Reverse Osmosis Systems

At Pure Process, we offer OSMO High-Pressure Reverse Osmosis systems (HPRO) which can operate at pressures of up to 160 bar! The standard operating pressure for RO systems treating well or brackish water is approximately 16 bar. Seawater plants, on the other hand, can run at pressures of up to 80 bar. The operating pressure of an HPRO is usually about 120 bar, which allows certain solutions to be concentrated near their solubility limit, maximising water recovery and recycling.

Our typical applications for RO / High-Pressure RO are:

Desalination of well water, process water, drinking water

Concentration of salts and organic solutions (scavenger solutions for CO2 capture)

Recycling of wastewater

Treatment and recovery of acids

Our expertise in chemical applications and separation technologies enables us to provide unique solutions to customers’ water, acid, and organics treatment challenges.

Maximum Recovery from Reverse Osmosis

Reverse osmosis plants for well and brackish water typically have a yield of 75 to 80 per cent. As a result, approximately 20 to 25% of the supplied water is discharged into the wastewater. When drinking water is used for reverse osmosis, there are significant purchase and disposal costs. With the OSMO Factor X, we have developed a system that can increase yield by more than 90% while halving wastewater production.

For high-salt wastewater or solutions that need to be concentrated, high-pressure reverse osmosis is recommended. With HPRO it is possible to reduce wastewater and to reintroduce valuable resources into your process.